Anode Carrier

Counter Weight

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor for Rodded Anode Transfer

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor for Spent Anode Transfer

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

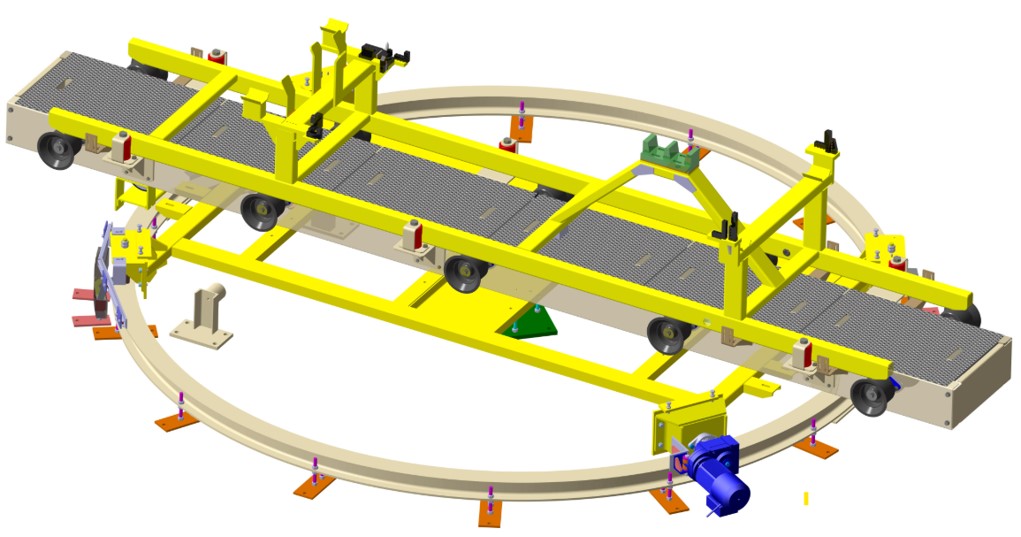

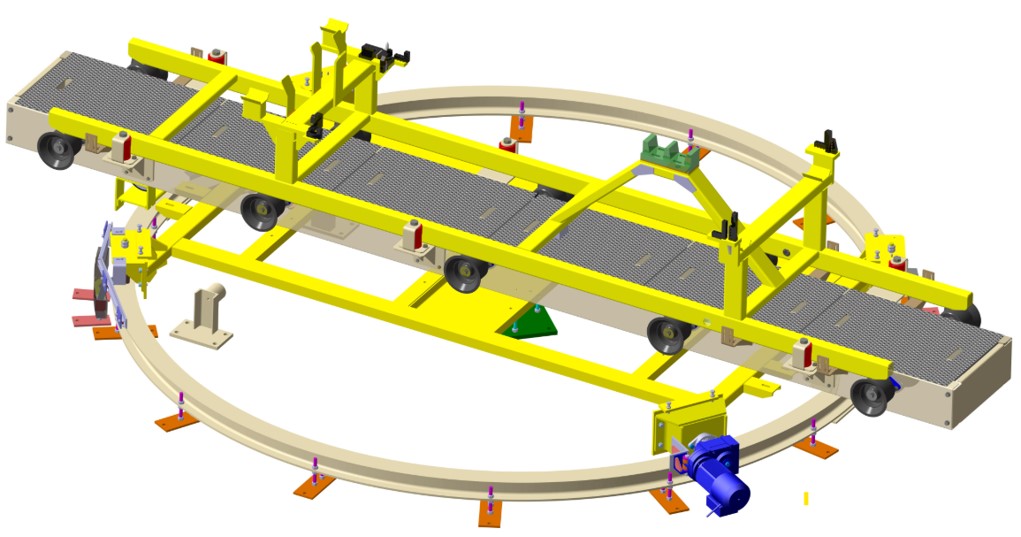

PnF system with Anode Carrier

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

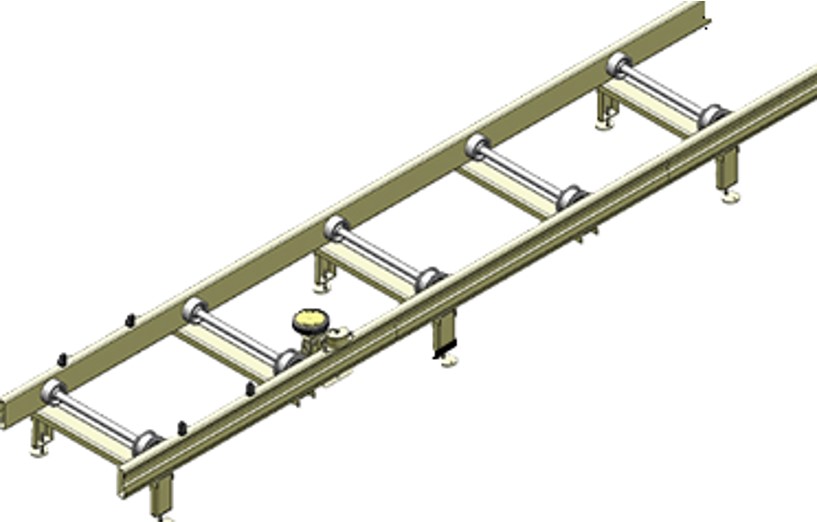

Roller Conveyor

Roller Conveyor

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Shot Blasting Machine

Shot Blasting Machine

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

EU9 Filter

Fine Filters

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

High Temp Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

High Temp Pre Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Pre Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Turn Table

Transfer Car

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Slat Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Single Mast lift

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Rivetless Chain

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PNF Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Monorail Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

FRB

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

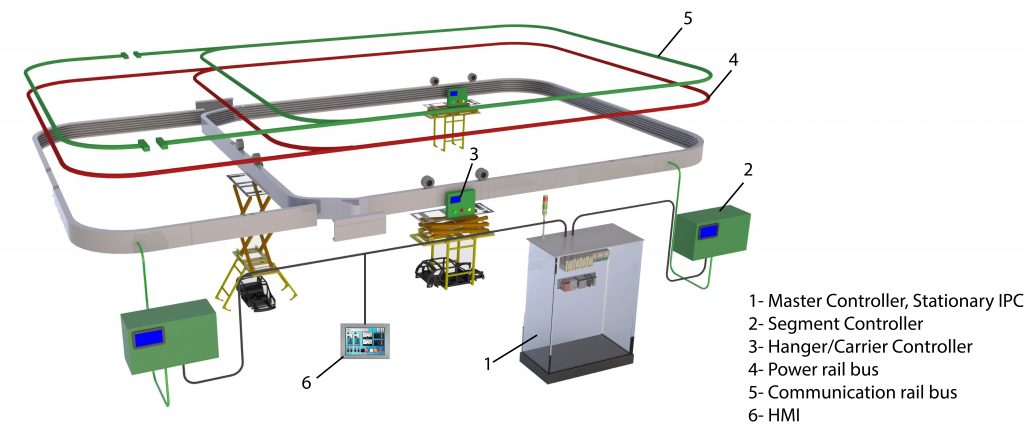

Automated Electrified Monorail System

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

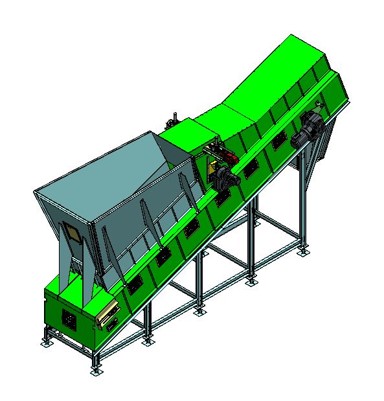

HoppFEED

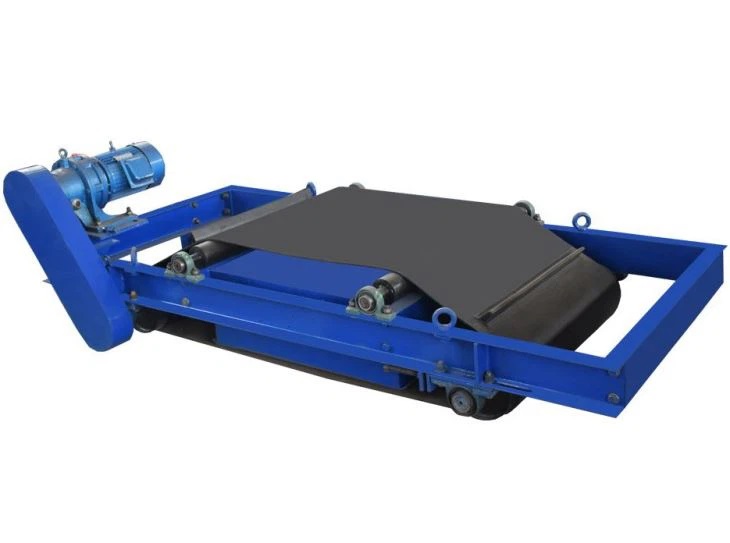

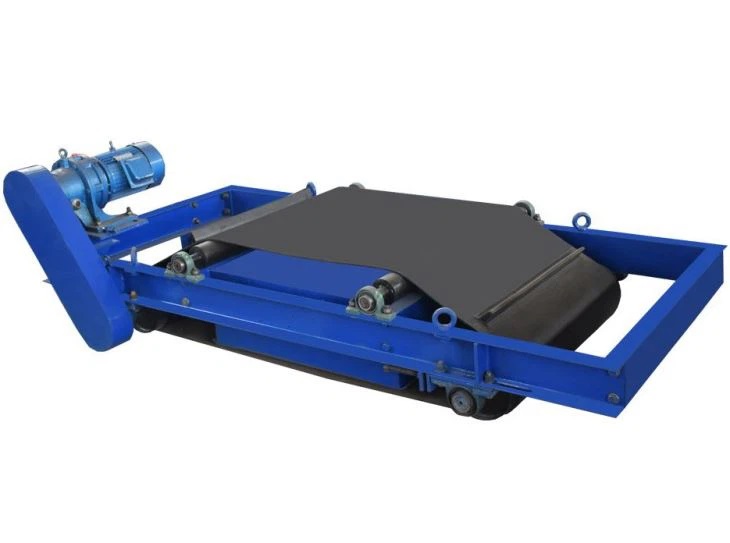

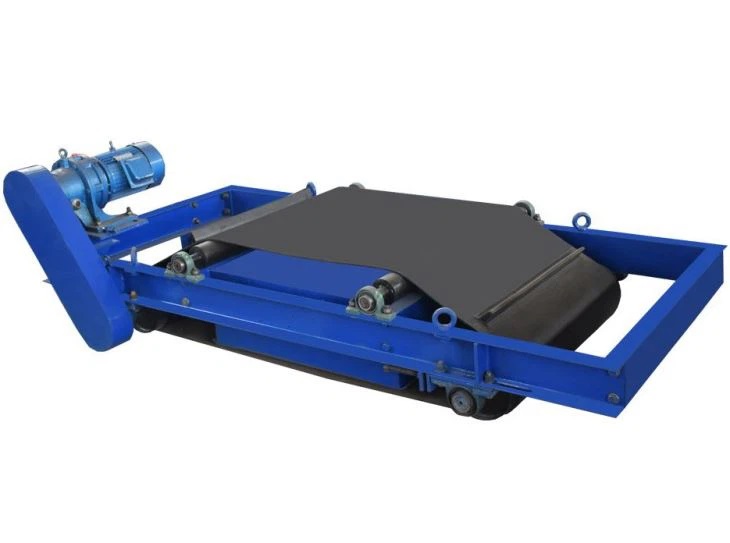

Magnetic Separator 2

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Belt Conveyor 2

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Belt Conveyor 5

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

HoppFEED

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Hopper

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Magnetic Sepeartor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Belt Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

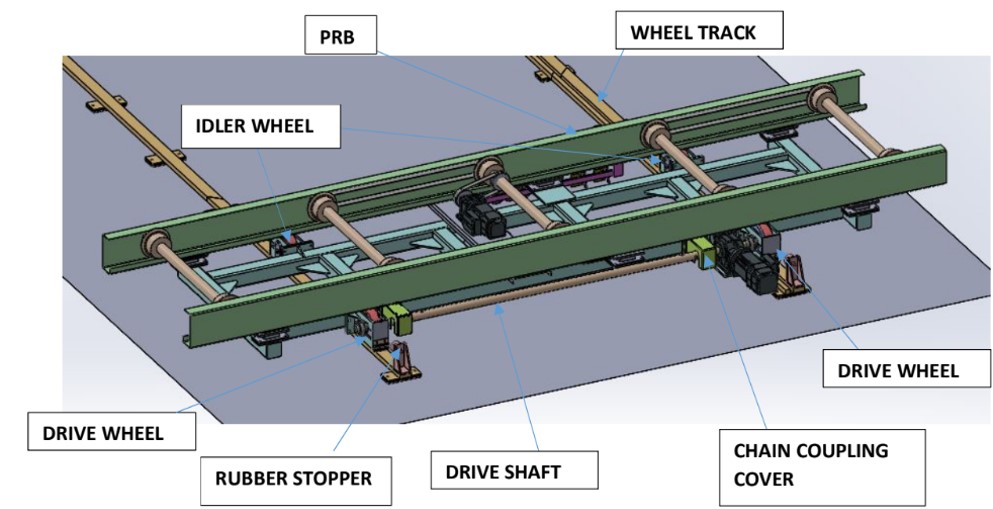

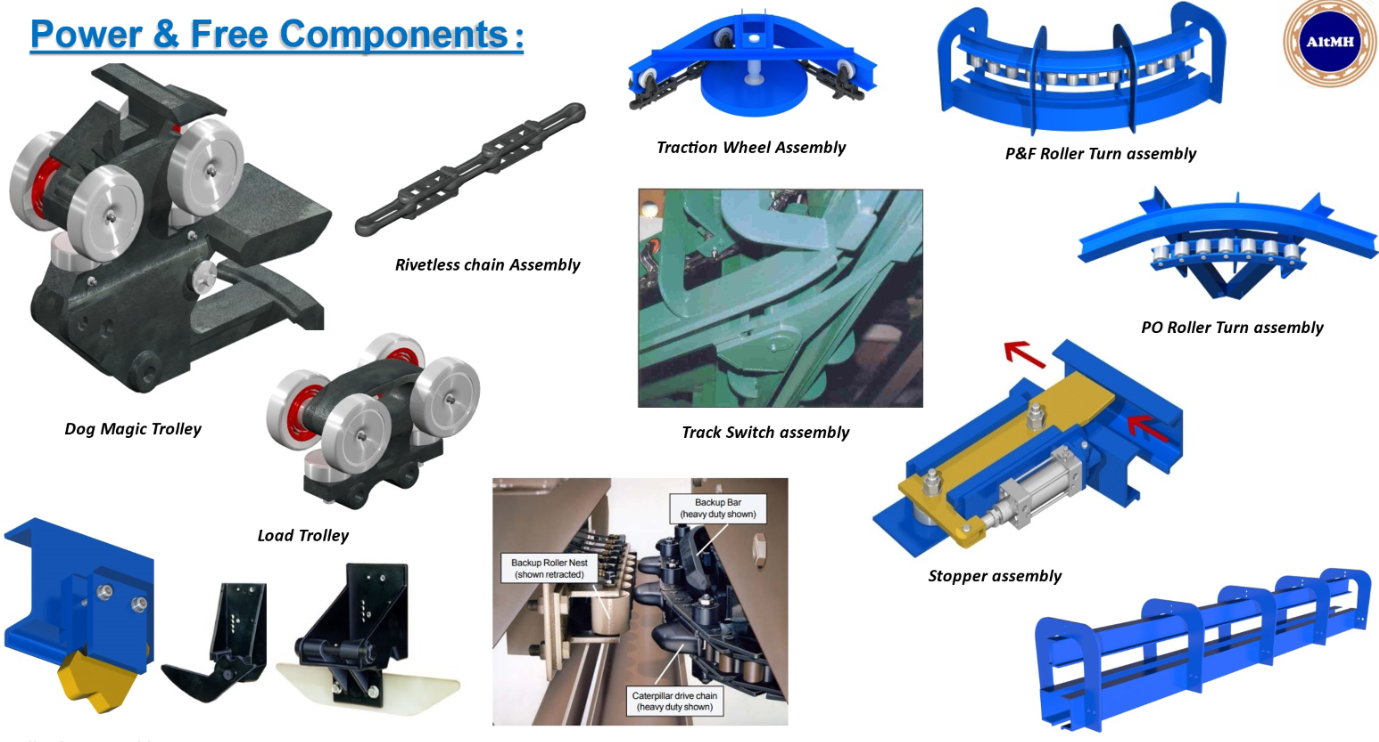

Power & Free Conveyor.

- Wide wing Power & Free conveyors are designed specifically to cater the typical industrial conveying requirement, for which conventional conveyors cannot be used. In the modern times, all the mass scale manufacturing is focused on flexible manufacturing system & cost-effective solution, exactly the same is offered with Variable chain speeds, high speed indexing, recirculation of products, balancing of operations & surge-stripping capabilities. These features make our conveyors the most useful & successful manufacturing tool for the user.

- Features of AltMH PnF Conveyors

- High-quality Components.

- Rugged Design

- Speed Variations.

- Elevation Changes

- Accumulation of components

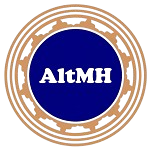

Power & Free Conveyor Spare Components

- Dog Magic Trolley

- Load Trolley

- Rivet-less drop forged chain x348, x458, x678

- Chain trolley Assembly

- Traction Wheel Assembly

- Roller Turn Assembly

- Stopper Assembly

- Drive Spares – Caterpillar chain, Backup-bar, Back Roller Assembly

- Track Switch Assembly

- P&F conveyor tracks.

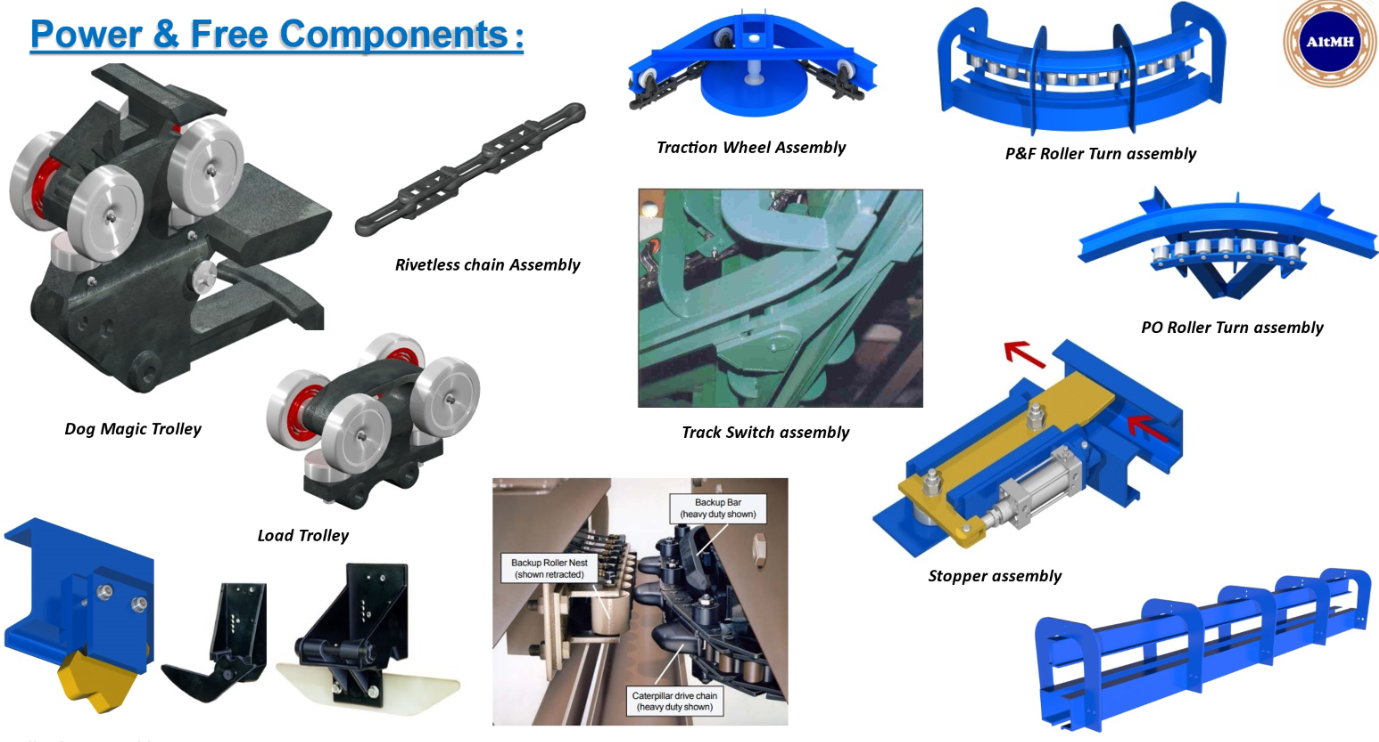

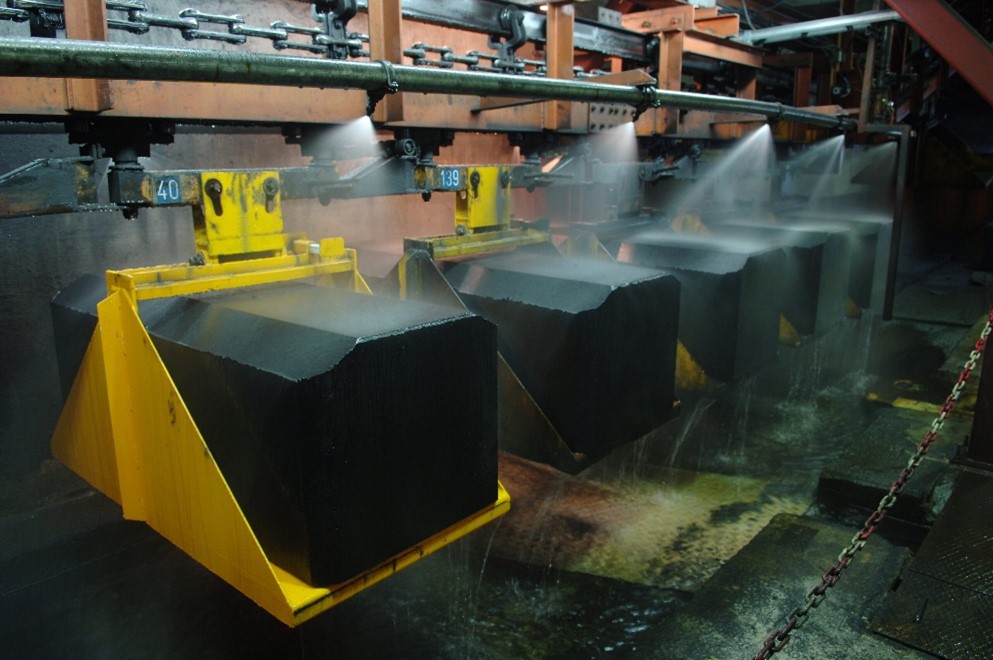

Green Anode Handling Carrier

- The shown carrier is used to transfer green anode at anode cooling shop

- Carrier can be constructed in Mild Steel structure / Aluminium Structure

Anode handling system at casting station

- We can supply anode handling system at casting station like Chain conveyor, Roller Conveyor, P&F Conveyor

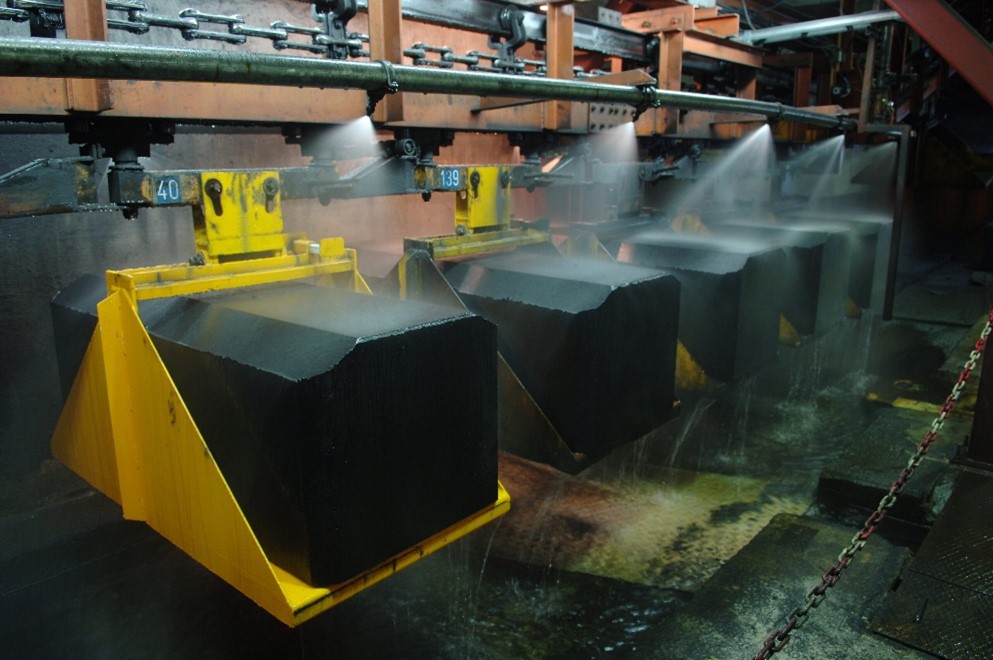

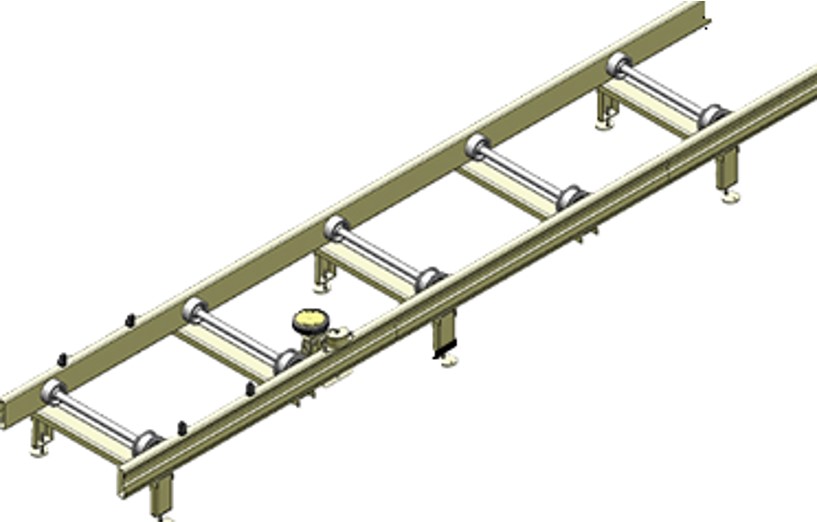

RollerConveyor

- Roller conveyors are the most versatile and economical material handling equipment for Anode transfer. Available in gravity or power-driven sections suitable for straight long runs or complex configurations. It is also modular and can be easily adjusted to meet current and future needs. Complete design, mechanical and electrical installations are available.

Chain Conveyors

- The Chain conveyors is used at to transfer the anode in Rodding shop.

Scissor Lift at Loading Unloading station r

- The Scissor lift used to lift anode at various stations..

Rod Holding Device

- The holding device used at cooling area after casting of anode in rodding shop.