Anode Carrier

Counter Weight

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

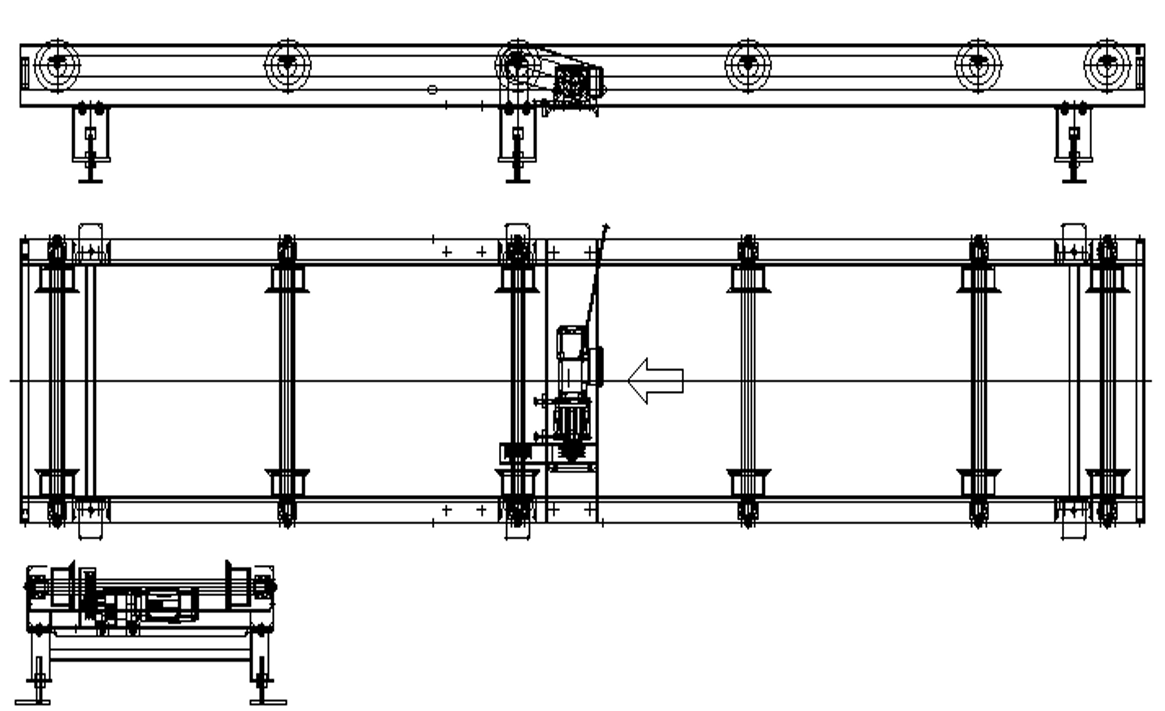

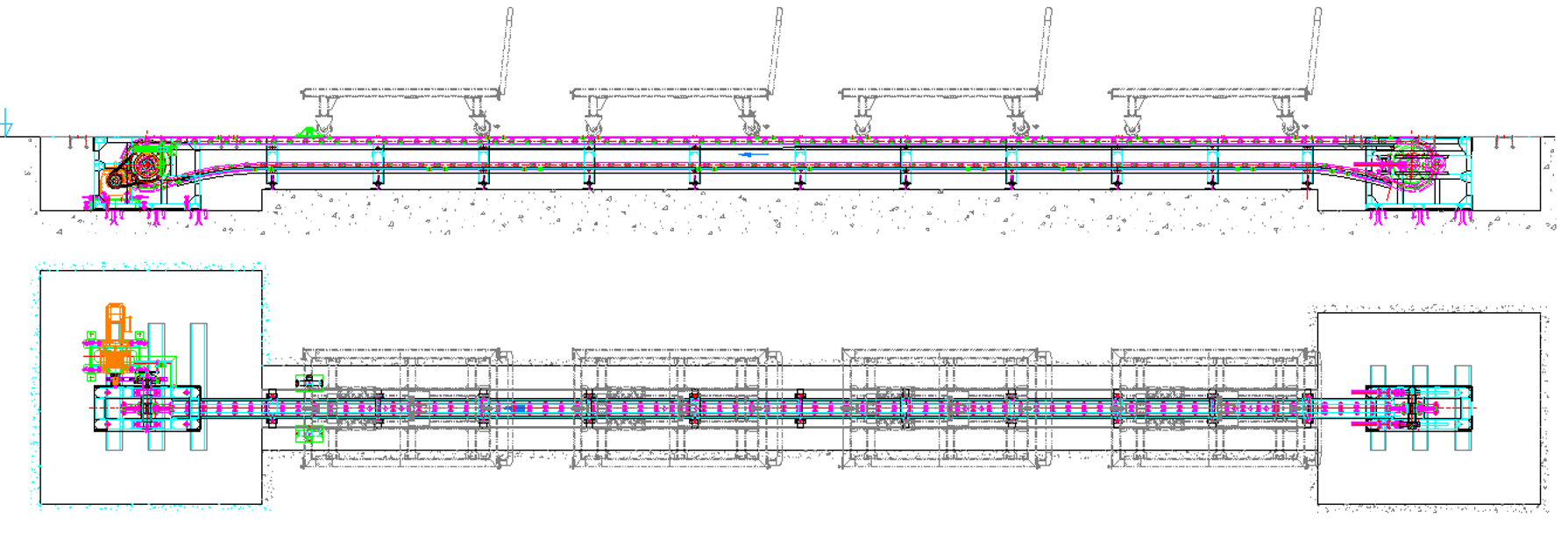

PnF Conveyor for Rodded Anode Transfer

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor for Spent Anode Transfer

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PnF system with Anode Carrier

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

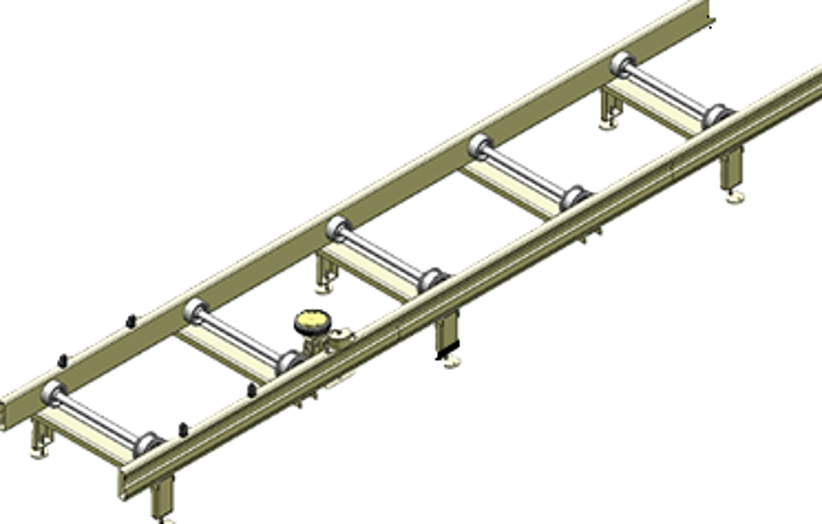

Roller Conveyor

Roller Conveyor

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Shot Blasting Machine

Shot Blasting Machine

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

EU9 Filter

Fine Filters

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

High Temp Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

High Temp Pre Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Pre Filter

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

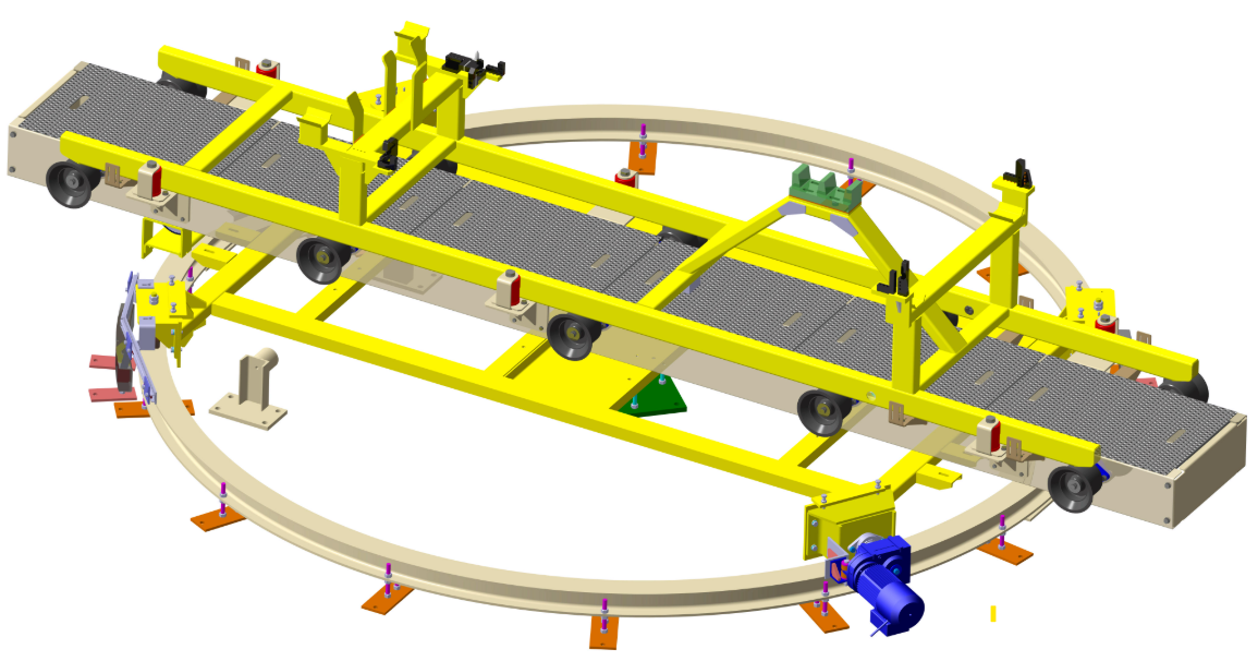

Turn Table

Transfer Car

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

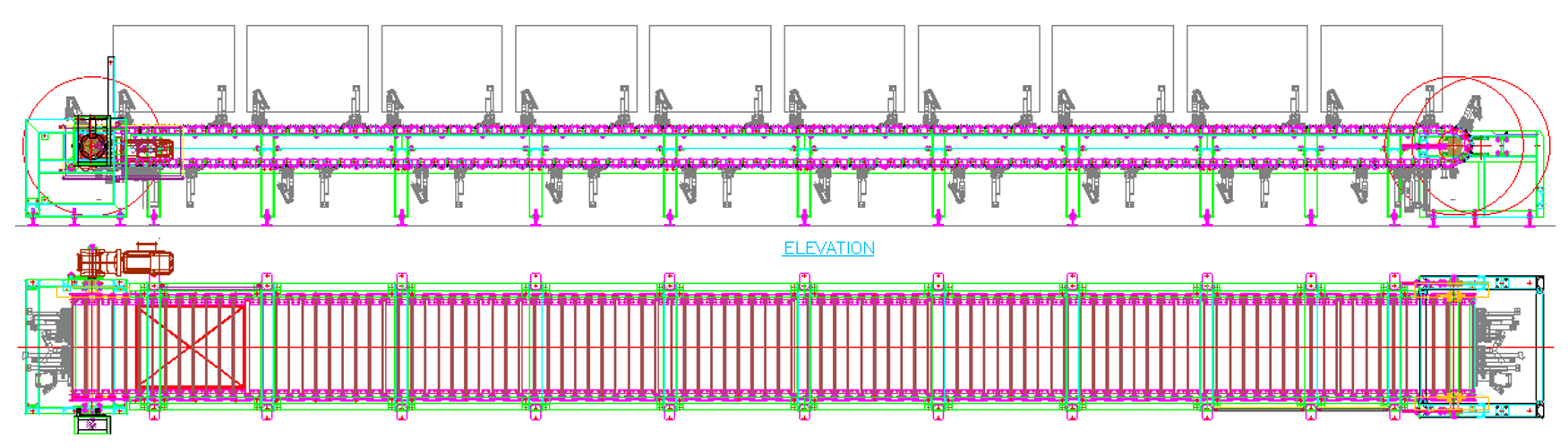

Slat Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Single Mast lift

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Rivetless Chain

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

PNF Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Monorail Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

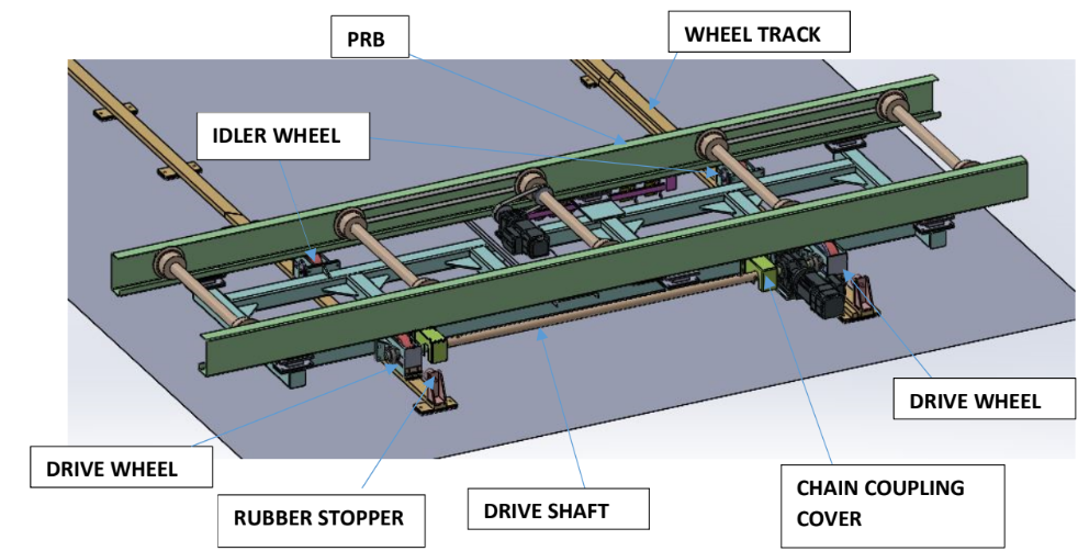

FRB

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Automated Electrified Monorail System

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

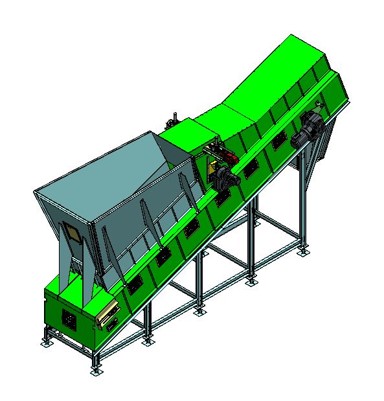

HoppFEED

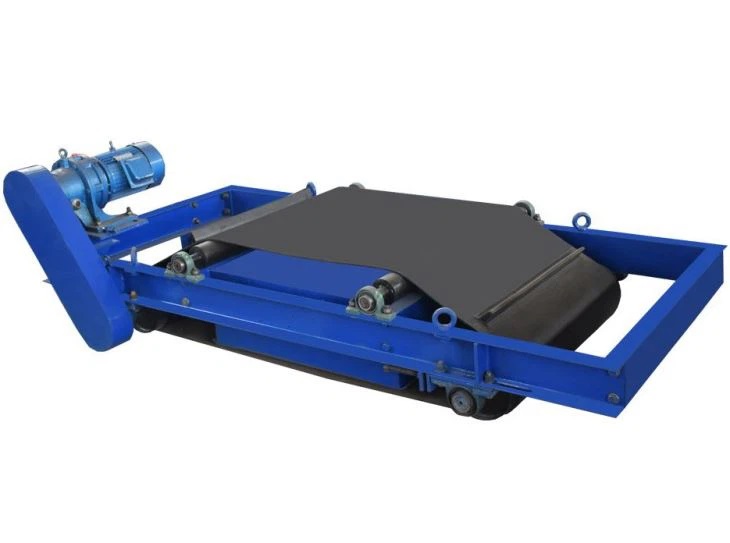

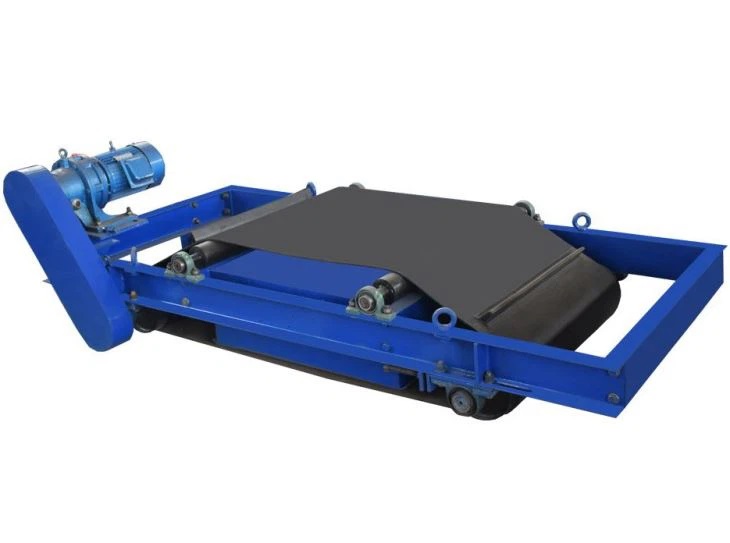

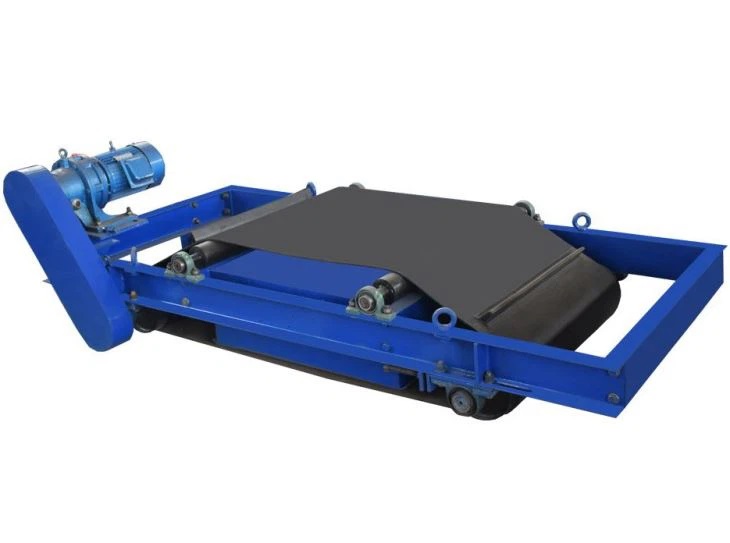

Magnetic Separator 2

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Belt Conveyor 2

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Belt Conveyor 5

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

HoppFEED

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Hopper

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Magnetic Sepeartor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

Belt Conveyor

Weight

950 kg

Dimensions

2.2 x 1.0 x 0.8 m

(7.2 x 3.2 x 2.6 ft)

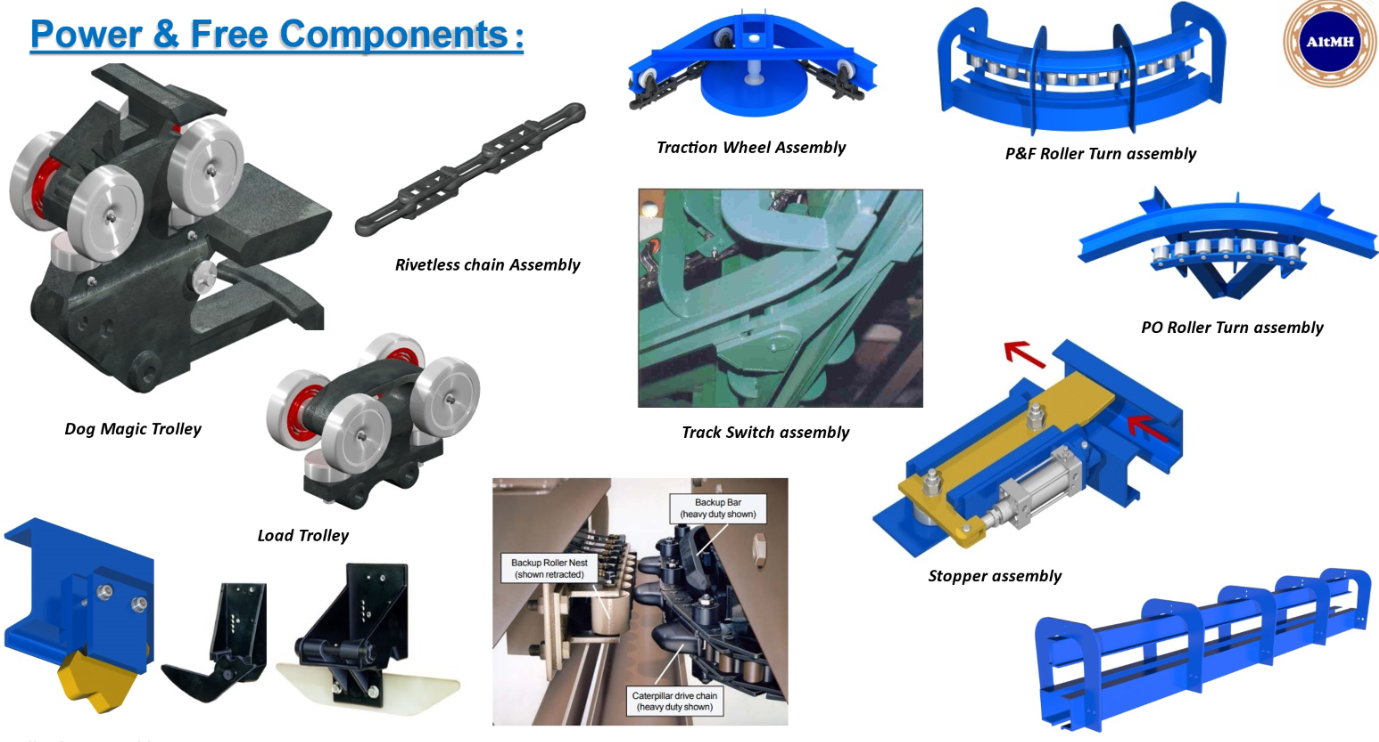

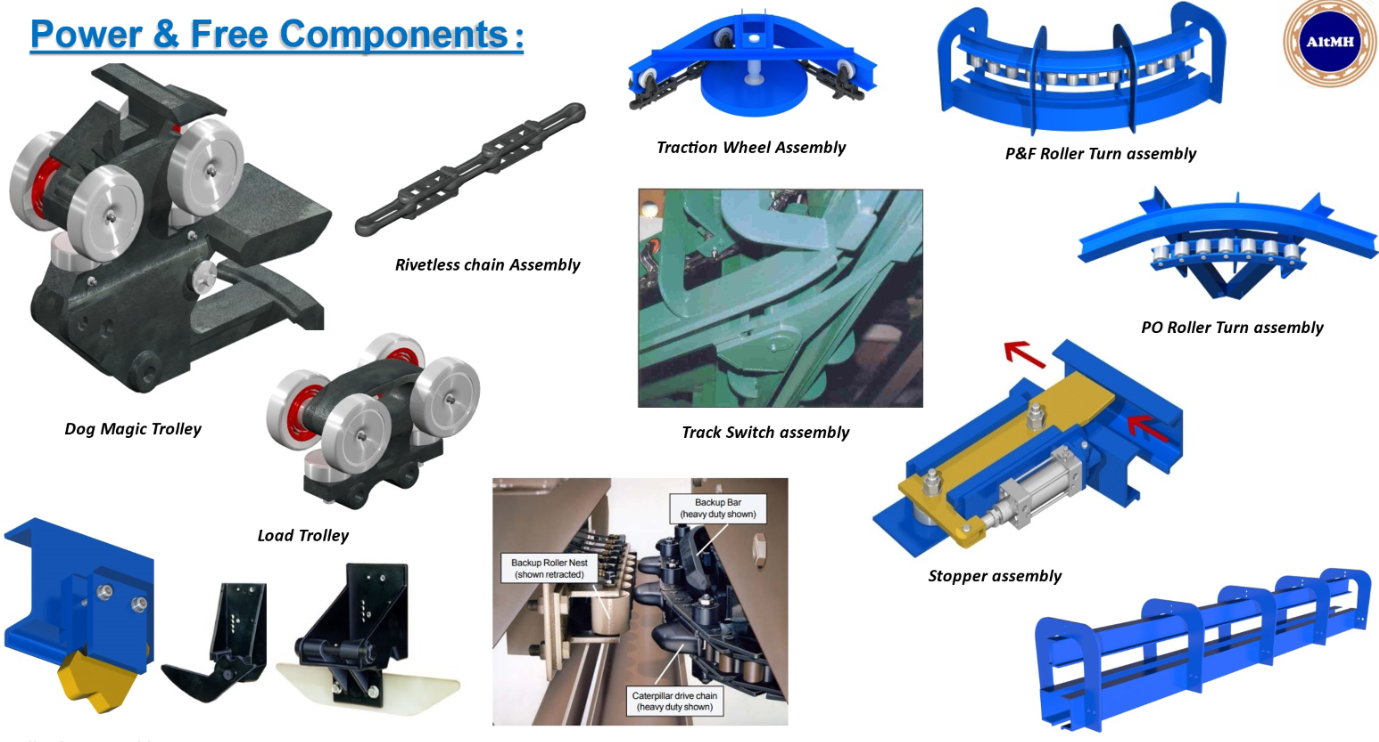

Power and Free Conveyor

- Wide wing Power & Free conveyors are designed specifically to cater the typical industrial conveying requirement, for which conventional conveyors cannot be used.

- In the modern times, all the mass scale manufacturing is focused on flexible manufacturing system & cost-effective solution, exactly the same is offered with Variable chain speeds, high speed indexing, recirculation of products, balancing of operations & surge-stripping capabilities. These features make our conveyors the most useful & successful manufacturing tool for the user.

- Features of AltMH PnF Conveyors:

- 1. High-quality Components

- 2.Rugged Design

- 3.Load Center of Speed Variations

- 4.ELevation Changes

- 5.High Density Accumulation

- 6.On-Line Storage and Segregation

.jpg)

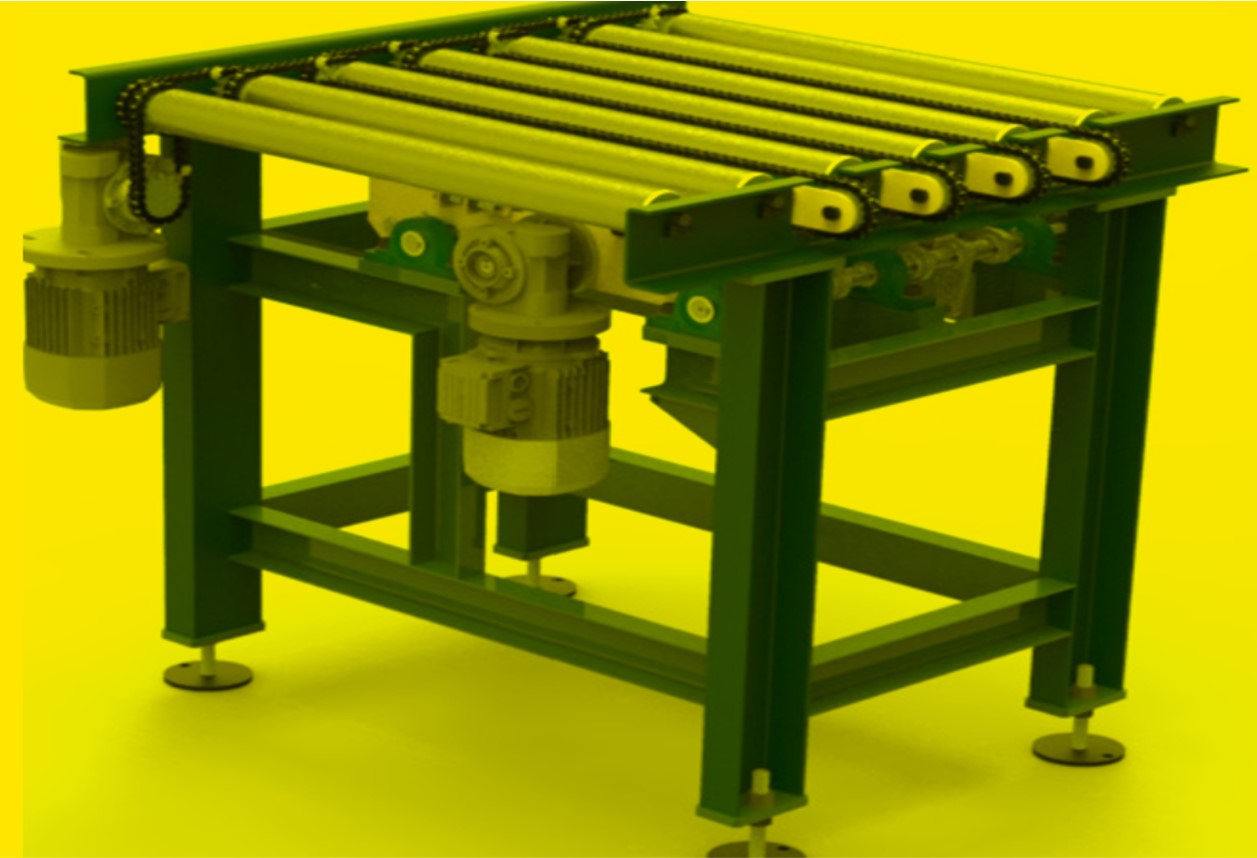

Power & Free Conveyor Spare Components

- Dog Magic Trolley

- Load Trolley

- Rivetless drop forged chain components for x348, x458, x678.

- Chain trolleys

- Traction Wheel Assembly

- Roller Turn Assembly

- Stopper Assembly

- Drive Spares – Caterpillar chain, Backupbar, Back Roller Assembly.

- Track Switch Assembly

- P&F conveyor tracks.

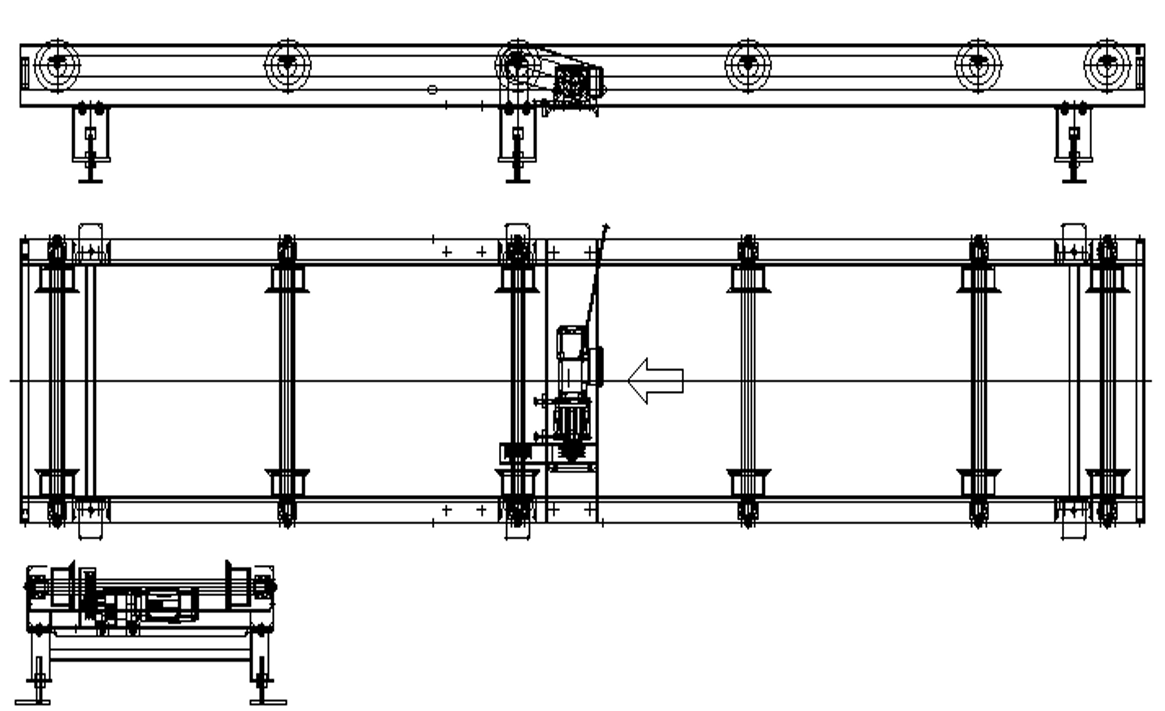

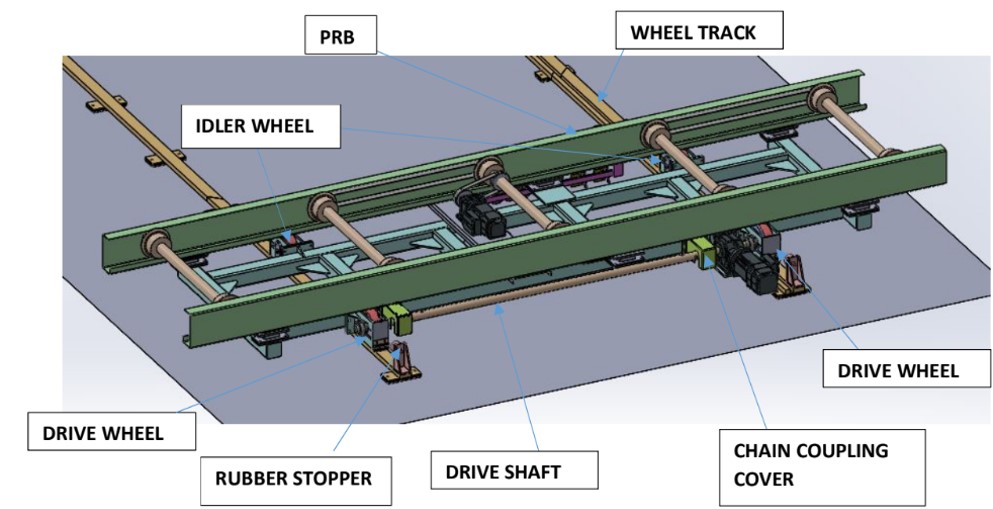

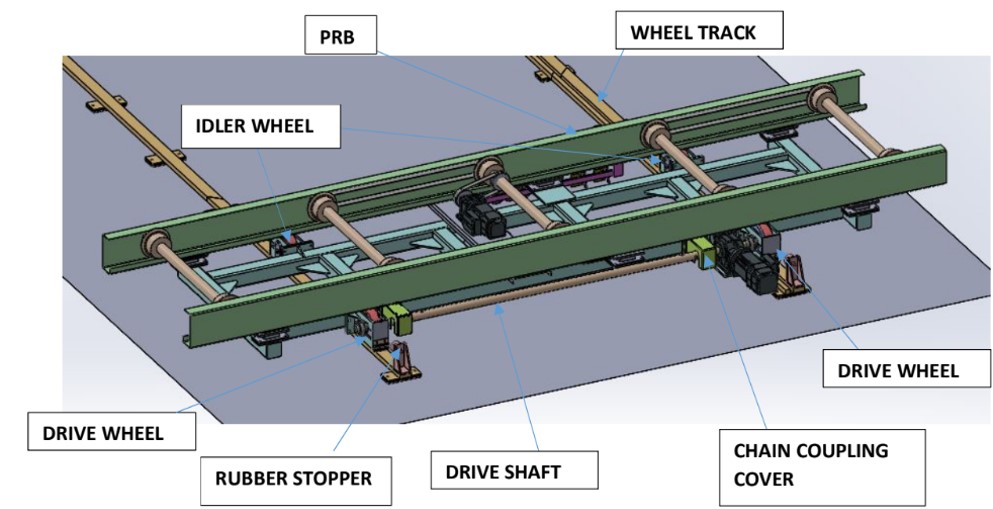

Power Roller Bed (PRB):-

- PRB (Power Roller Bed) conveying system is key for all types of industrial body/object transfers using different types of skids. Basic construction of PRB as given below.

- PRB may be mounted on Transfer car ,Turn table, Lifter as per application requirement. .

- The PRB rollers should be PU coating or metallic depends on application.

- We can also provide spares or maintenance support for your present system.

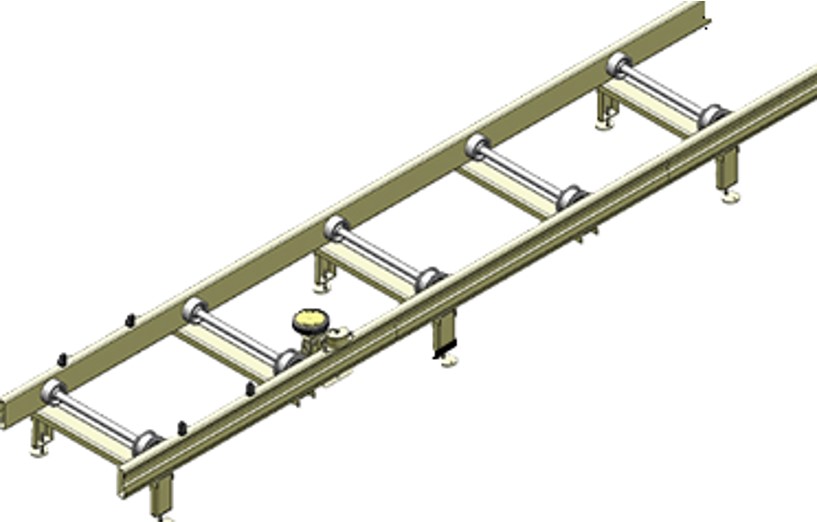

Friction Roller Bed (FRB):-

- FRB (Friction roller Bed) is skid conveying system with combination of Idle roller sets and Friction pulleys to transfer the skid forward. .

Transfer Car (Shuttle Car)-(TC)

- Transfer car(shuttle) is used to transfer the skid/pallet in lateral direction which furtheer align with various conveyors row to transfers the material in a particular row. Transfer car is generally combination of TC+PRB or TC+TT(TURN TABLE) or TC with FRB/FDS

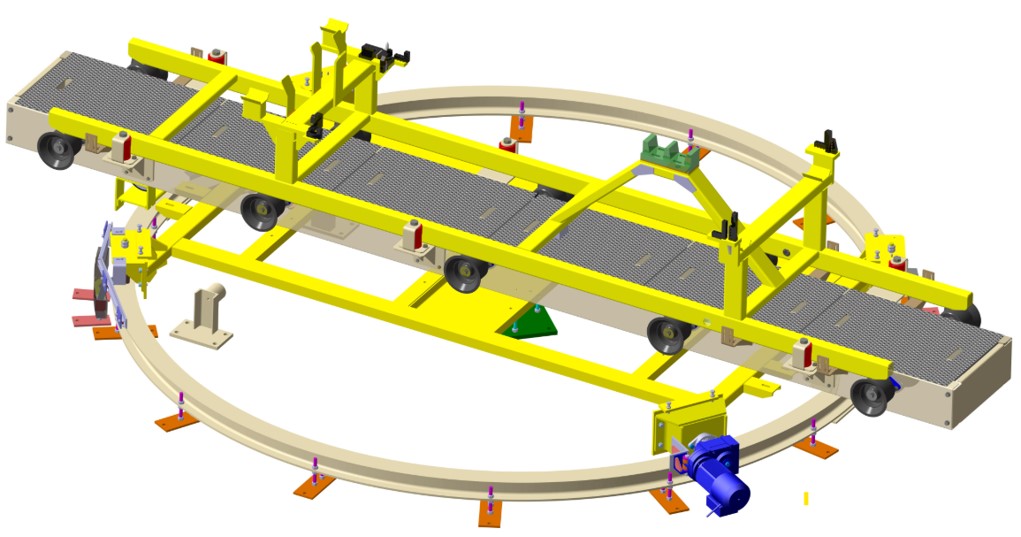

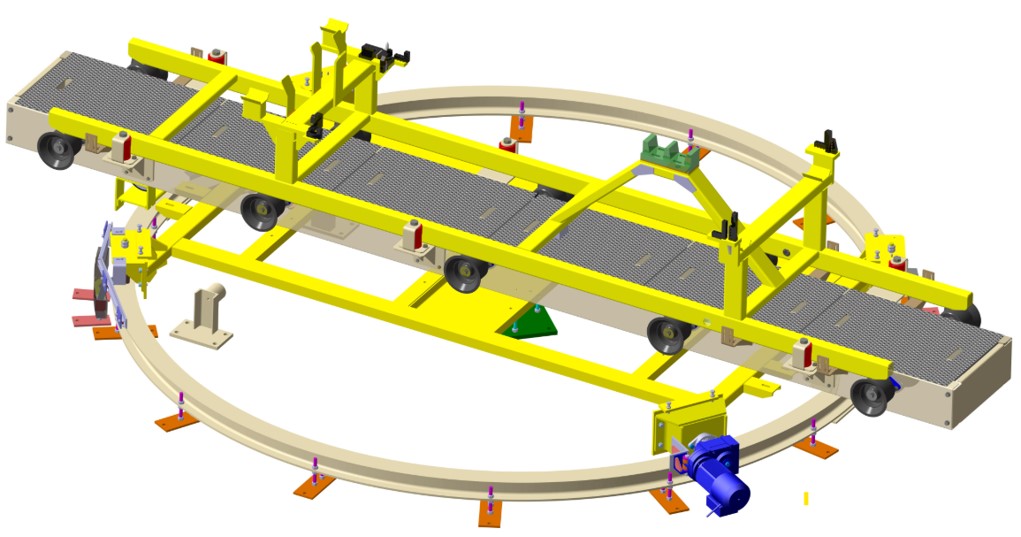

Turn Table-(TT)

- Turn table is used to change orientation of Skid. Sizes and design will be as per product to be Handled.

- Turntables are integral to improving the flow of materials and parts in a highly efficient and cost-effective manner in the automobile industry.

Lifter with PRB/Roller conveyor

- Lifter will be used to transfer Vehicle with skid from one level to another level. Roller bed in line is used to receive and deliver Skid with Vehicle to the lifter unit. Single mast lifer unit will be used to transfer pallet with object from one level to another level.

- Roller conveyor in line is used to receive and deliver Pallet with body to the lifter.

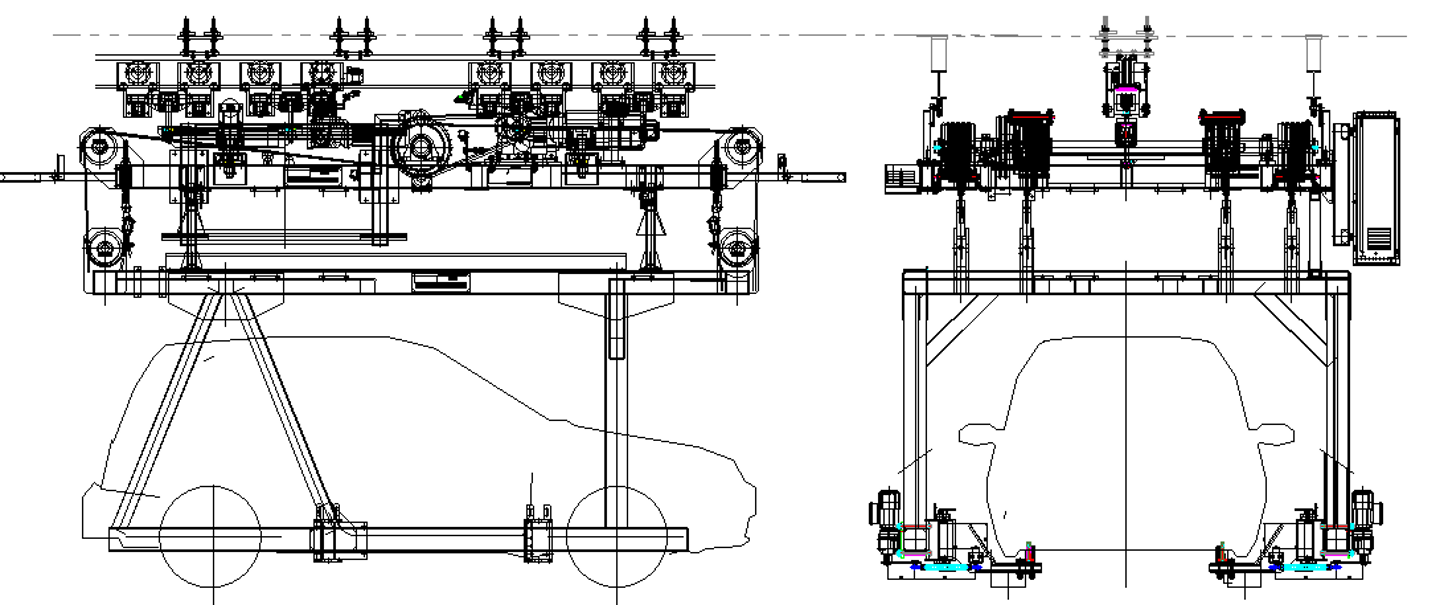

EMS (Electrified Monorail System)

- EMS is a transport system where vehicles are suspended from a single rail, often referred to as a monorail.

- Parts of EMS

- EMS Advantages -

Low noise, clean installation, Oil-free, Energy efficient and Modular.

- 1. EMS Carrier with Automated Arms.

- 2. Aluminium EMS tracks.

- 3. Fail safe Track switches.

Slat Conveyor

- Slates are mounted at particular pitch on the conveyor chain with K2 attachment as per decided pitch in design.

- The chain link decides the Slat pitch distance. Fixture arrangement can be designed on a Single Slat or combination of adjacent Slates as per the product resting point geometry.

Monorail

- A single rail is used in Monorail Systems to move components and materials along a predefined route. An overhead monorail system is an excellent choice when moving parts between stations in an assembly line, staging parts in a paint booth or other similar application, or storing or awaiting parts overhead to save floor space.

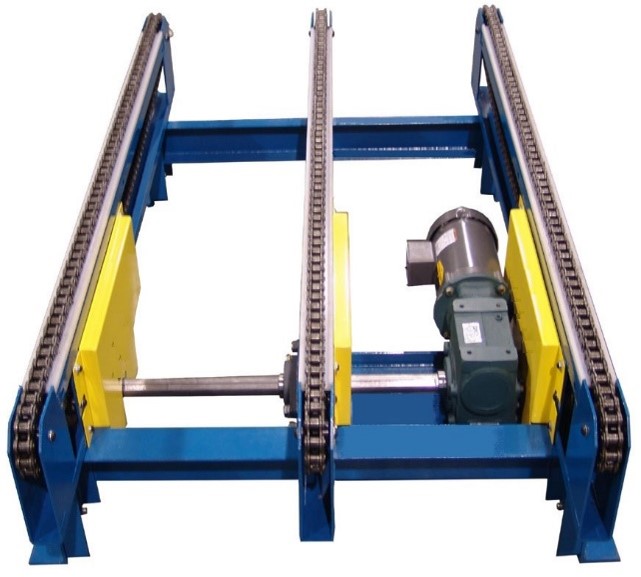

Chain Conveyor

- Chain conveyors are primarily used to transport heavy unit loads, e.g. pallets, grid boxes, and industrial containers.

- These conveyors can be single or double chain strand in configuration.

- The load is positioned on the chains, the friction pulls the load forward.

- Chain conveyors are generally easy to install and have very minimum maintenance for users.

- Features of AltMH Chain Conveyors:

- 1. Simple in construction.

- 2. Very easy to install & minimal maintenance.

- 3. Flexibility in applications as well as environments..

- 4.Variable speed option (by using VFDs).

- 5. On-Line Storage and Segregation.

AEM (Automated Electrified Monorail System):

- Parts of AEM-

- 1. AEM Carrier with Automated Arms. .

- Aluminum AEM tracks.

- Fail safe Track switches. .

- Advantages

- Low noise, Clean installation, Oil-free, Energy efficient and Modular. .

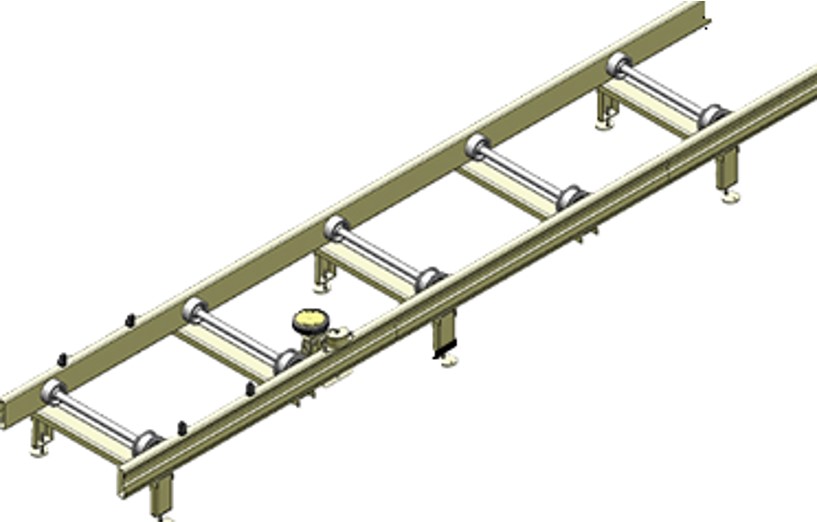

Roller Conveyor

- Roller conveyors are the most versatile and economical material handling equipment. Available in gravity or power-driven sections suitable for straight long runs or complex configurations. Powerline roller conveyors require less drive to operate than power line conveyors. It is also modular and can be easily adjusted to meet current and future needs. Complete design, mechanical and electrical installations are available.